FPC Stiffener (FPS)

FPC stiffener is a common and important requirement for a flexible PCB to bolster the rigidity of specific areas of flex or rigid-flex circuits by improving their durability and reliability. It is a mechanical support part or heat dissipation element, which significantly influences the reliability of flexible printed circuits, and it can be bonded on one or two sides of the specific areas of flex. Our FPC stiffener (FPS ) is made up of our high-performance polyimide film and a high-reliability room-temperature type of thermosetting adhesive. The thickness of the FPS is mainly considered according to the design drawings and the use environment.

It is most commonly applied in the area on the back of the FPC golden fingers, which will be inserted into the ZIF connector. It can also be used as a substrate for FPC to protect delicate components from damage due to handling and mechanical stresses. Our FPS provides excellent solder resistance and high bonding strengths with PET, FR4, PI, and PCB. It is an ideal solution in many designs for improving the durability and reliability of the flex circuits.

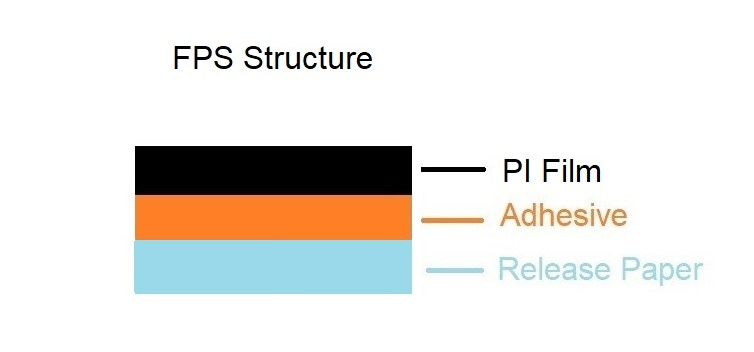

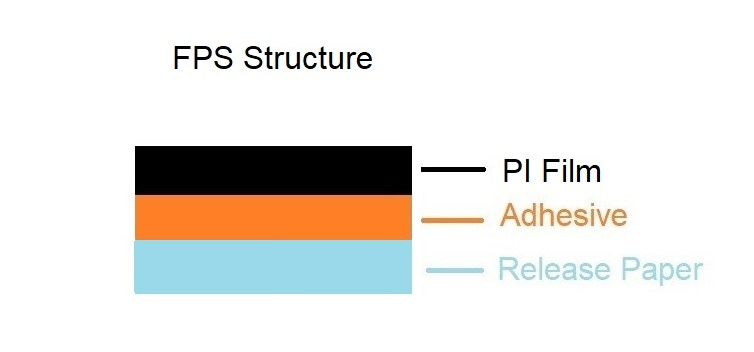

FPS Stiffener Structure:

Top Layer: Polyimide film (1mil~9mil)

Middle Layer: Thermosetting Epoxy Adhesives (25um/35um)

Bottom Layer: Release Paper (135um)

Features & Properties:

1, High peel strength for Aluminum: 16N/10mm by using 90° peeling test way.

2, Excellent peel strength for PI film: 25N/10mm by using 90° peeling test way.

3, Outstanding soldering resistance: No functionality failure & deformability by immersing into the soldering reflow process at 260°C for

60 seconds.

4, Good storage condition: It can keep good functionality at room temperature for 4~6 months.

Application Categories:

1, Component/Connector Stiffeners.

2, ZIF Stiffeners.

3, Localized Bend constraints.